When it comes to precision and efficiency in manufacturing, cnc milling machines have become an indispensable tool. These machines utilize computer numerical control (CNC) technology to automate the milling process, resulting in faster production times and higher accuracy.

The Versatility of CNC Milling Machines

CNC milling machines are capable of handling a wide range of materials, including metals, plastics, and composites. With their ability to perform complex cuts and shapes with ease, they have revolutionized industries such as aerospace, automotive, and medical device manufacturing.

These machines offer various specifications that cater to different needs. For instance, some models come equipped with multiple axes for simultaneous machining operations while others focus on high-speed cutting capabilities. Additionally, advanced features like automatic tool changers further enhance productivity by reducing downtime between operations.

The Innovation by Conprofe Ultrasonic

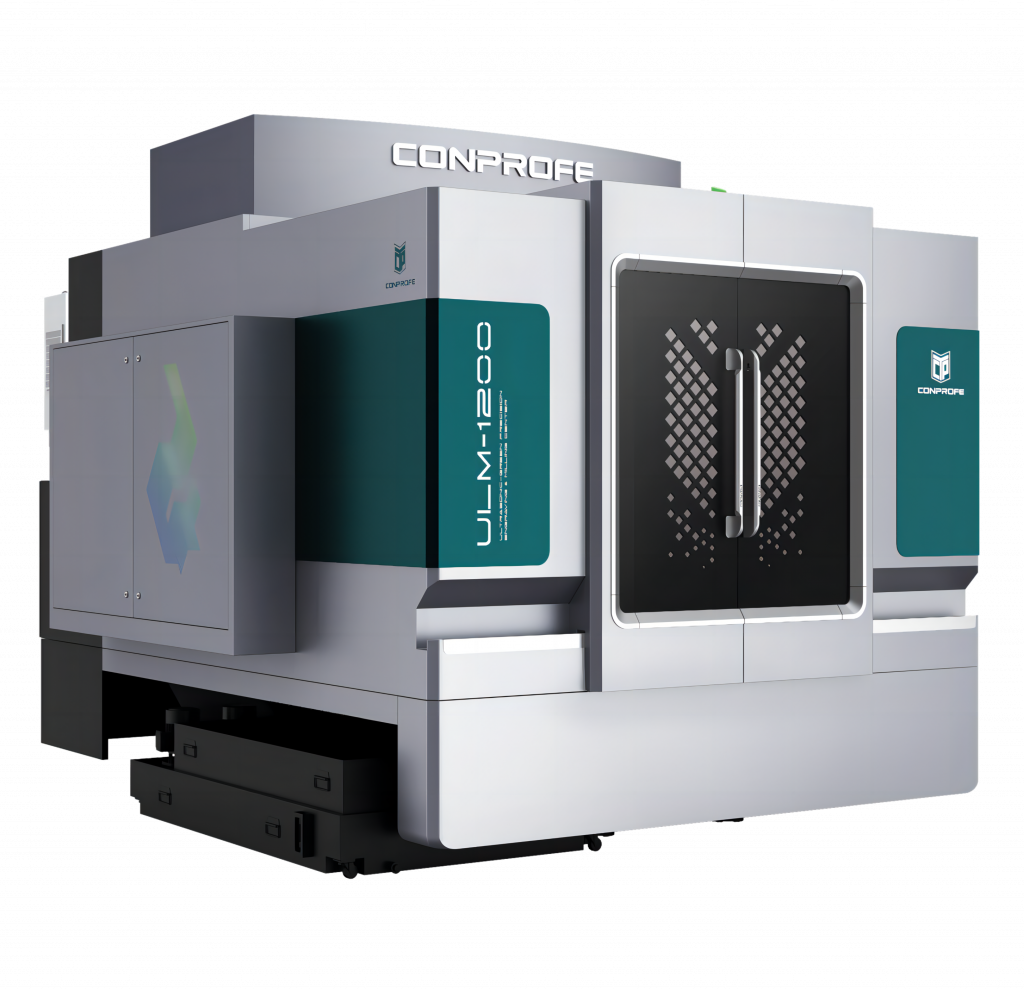

One notable player in the field is Conprofe Ultrasonic. They have introduced ultrasonic-assisted machining technology into CNC milling machines. This innovation utilizes high-frequency vibrations to reduce friction during the cutting process, resulting in improved surface finish quality and extended tool life.

In addition to its benefits for traditional materials like metal alloys or ceramics, this technology has also shown promising results when applied to challenging materials such as carbon fiber-reinforced polymers (CFRP). By minimizing delamination and burr formation during CFRP machining processes through ultrasonic assistance, Conprofe Ultrasonic has opened up new possibilities for industries seeking lightweight yet strong components.

Machining Center Manufacturers Embrace Automation

machining center manufacturers are continuously pushing boundaries by integrating automation solutions into their CNC milling machines. This trend aims at streamlining production processes while maintaining consistent quality standards.

Some manufacturers have incorporated robotic arms into their machines, enabling automated loading and unloading of workpieces. This not only reduces manual labor but also enhances safety by minimizing human-machine interaction.

Furthermore, the integration of artificial intelligence (AI) algorithms allows for real-time monitoring and adjustment of machining parameters. By analyzing data from sensors embedded in the machine, AI can optimize cutting speeds, tool paths, and feed rates to achieve optimal results while reducing waste.

In Conclusion

CNC milling machines continue to evolve with advancements in technology. From their versatility in handling various materials to innovations like ultrasonic-assisted machining and automation solutions offered by companies such as Conprofe Ultrasonic and other machining center manufacturers, these machines are revolutionizing manufacturing processes worldwide. As industries strive for higher efficiency and precision, CNC milling machines will undoubtedly play a crucial role in shaping the future of production.