In this tutorial, I will provide an overview of the concept of overmolding and its significance in various industries. Overmolding refers to a process where two or more materials are combined to create a single finished product. This technique offers numerous advantages such as improved functionality, enhanced aesthetics, and increased durability.

Click to find more about what is overmold.

The Basics of Overmold

Overmolding involves the use of two different materials: a base material and an overmold material. The base material forms the structural component of the product, while the overmold material is applied on top to provide additional features or benefits. Common examples include adding soft-touch grips to tools or creating non-slip surfaces on handles.

This process typically utilizes 2k injection molding technology, which allows for precise control over both materials’ placement and bonding strength. By injecting molten thermoplastic polymers into a mold cavity sequentially or simultaneously, manufacturers can achieve seamless integration between multiple materials.

The 2k Injection Molding Process

The 2k injection molding process involves several steps that ensure proper adhesion between the base and overmold materials:

- Melt Preparation: Each material is melted separately in their respective injection units at specific temperatures suitable for their properties.

- Injection: The first shot injects the base material into the mold cavity partially or completely depending on design requirements.

- Mold Rotation/Transfer: After cooling down slightly but still being semi-solid, the mold rotates or transfers to another station where it receives the second shot—the overmold material—onto specific areas designated by designers.

- Bonding: As both shots cool down further inside the mold cavity, they bond together firmly due to molecular interlocking at their interface points.

- Ejection: Once the overmolded part is fully solidified, it is ejected from the mold for further processing or assembly.

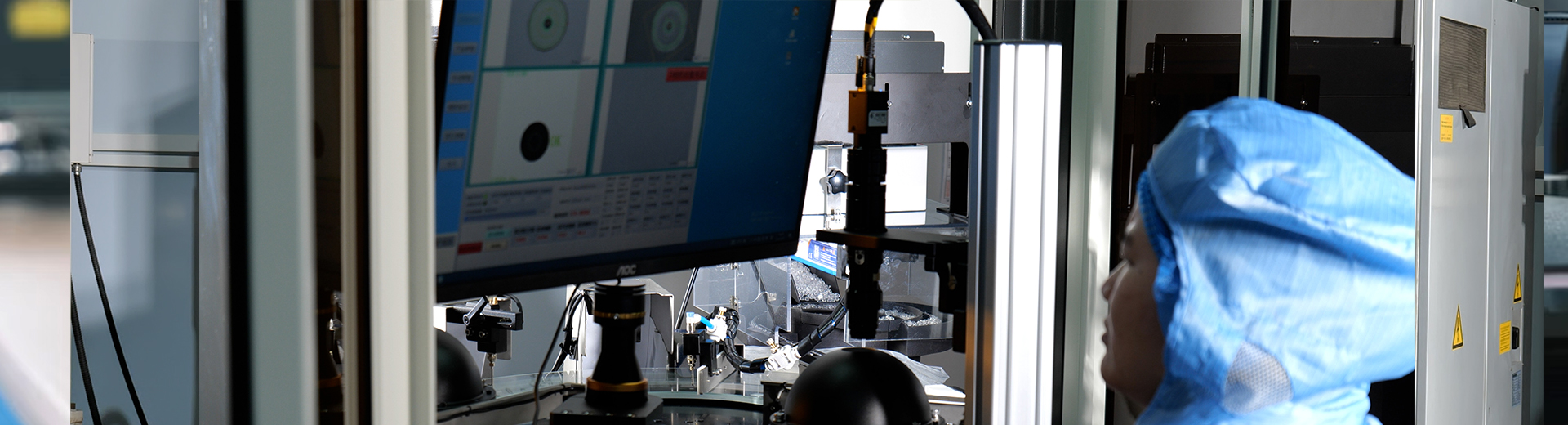

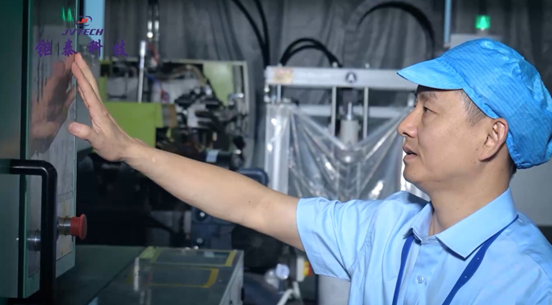

JVTECH’s Expertise in Overmolding

As a leading provider of manufacturing solutions, JVTECH specializes in overmolding techniques. With state-of-the-art facilities and a team of experienced engineers, we offer comprehensive services to meet diverse customer needs.

We work closely with our clients throughout the entire product development process, from design consultation to prototyping and mass production. Our expertise in material selection, tooling design, and process optimization ensures high-quality overmolded products that exceed customer expectations.

Conclusion

In conclusion, overmolding is a versatile manufacturing technique that combines multiple materials to create innovative and functional products. The 2k injection molding process plays a crucial role in achieving seamless integration between different materials. At JVTECH, we have the knowledge and capabilities to deliver exceptional results through our expertise in overmolding technology. Contact us today to discuss your project requirements!